Contents:

Pasteurization is a process used primarily in the food industry to destroy harmful microorganisms in food and prolong shelf life. The process was developed by French scientist Louis Pasteur in 1864 and is named after him. Pasteurization is used for a variety of food products, including milk, cheese, yogurt, juice, and other beverages.

Definition of Pasteurization

Pasteurization is a process that involves heating food to a specific temperature for a defined period of time to kill any pathogenic microorganisms that may be present. The temperature and time of the pasteurization process vary depending on the type of food being pasteurized.

The primary goal of pasteurization is to destroy pathogenic microorganisms, which can cause foodborne illness. Microorganisms, such as bacteria, viruses, and parasites, can be present in raw or unpasteurized food and can cause serious health problems, including stomach cramps, diarrhea, and vomiting.

History of Pasteurization

Pasteurization was discovered by Louis Pasteur, a French scientist, in 1864. Louis Pasteur discovered that heating wine to a specific temperature and holding it there for a certain amount of time killed the microorganisms that caused spoilage and improved the shelf life of the wine.

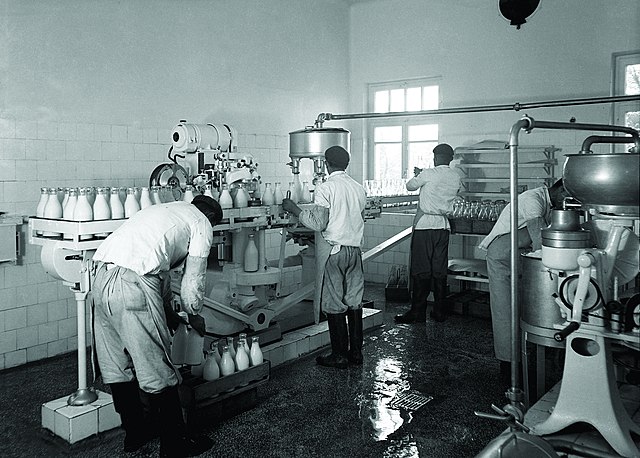

Pasteurization was quickly recognized as an effective means of improving the safety and shelf life of food products. In the late 1800s, pasteurization was used to extend the shelf life of milk, which was a major cause of foodborne illness at the time. As a result, pasteurization became a common practice in dairy processing.

Types of Pasteurization

There are three main types of pasteurization: high-temperature short-time (HTST) and ultra-high-temperature (UHT) pasteurization.

1. High-Temperature Short-Time (HTST) Pasteurization

HTST pasteurization involves heating milk to 72°C for 15 seconds. This process is designed to kill the majority of the microorganisms present in milk, including harmful bacteria such as Salmonella and Escherichia coli (E.coli).

HTST pasteurization is a popular method for pasteurizing milk and other dairy products. It is relatively quick and does not significantly alter the taste or nutritional content of the milk. HTST pasteurization is also relatively cost-effective, making it an attractive option for large-scale dairy processing operations.

2. Ultra-High Temperature (UHT) Pasteurization

UHT pasteurization involves heating milk to 135°C for 1-2 seconds. This process is designed to kill all of the microorganisms present in milk, including beneficial bacteria such as lactobacilli.

UHT pasteurization is a popular method for pasteurizing milk and other dairy products because it destroys all microorganisms and extends shelf life. UHT pasteurized milk does not require refrigeration until it is opened, making it highly convenient for consumers.

3. Batch Pasteurization

Batch pasteurization is a slow process that involves heating milk to a temperature of at least 63°C (145°F) for 30 minutes, followed by rapid cooling. This process is mainly used for smaller volumes of milk and dairy products, such as cheese and yogurt.

Comparison of Pasteurization Methods

Each type of pasteurization has its own advantages and disadvantages. HTST pasteurization is quick and efficient but is not suitable for long-term storage. UHT pasteurization is effective for long-term storage and transport but can affect the flavor and texture of some products. Batch pasteurization is slower but gentler, which preserves the flavor and texture of some products, but is not as efficient as the other methods.

Process of Pasteurization

The process of pasteurization involves heating the food to a specific temperature and holding it there for a specified time. The temperature and time of the process depend on the type of food being pasteurized.

- Heat the Food to a Specific Temperature

The first step in pasteurization is to heat the food to a specific temperature. The temperature and time of the heating process depend on the type of food being pasteurized.

- Hold the Food at that Temperature for a Defined Time

Once the food has reached the target temperature, it is held at that temperature for a specified period of time. This allows the heat to penetrate the food and kill any microorganisms that may be present.

- Rapid Cooling

After pasteurization, the food is rapidly cooled to prevent any further growth of microorganisms that may have survived the heat treatment.

Comparison of Pasteurization and Sterilization

Pasteurization is different from sterilization, which is a process that eliminates all microorganisms, including beneficial ones. Pasteurized food may still contain some non-pathogenic bacteria, while sterilized food is completely free of microorganisms.

Sterilization is often used in medical settings to prevent the spread of disease. In the food industry, sterilization is typically used for canned goods and other shelf-stable products that must have a shelf life of several years.

Uses of Pasteurization

Pasteurization is commonly used in the food industry to improve food safety and prolong shelf life. Some common uses of pasteurization include:

- Milk and Dairy Products

Pasteurization is commonly used to pasteurize milk and other dairy products such as cheese, yogurt, and cream. This helps to ensure the safety and prolong the shelf life of these products.

- Juice and Other Beverages

Pasteurization is also commonly used to pasteurize juices and other beverages. This process helps to destroy any pathogenic microorganisms that may be present in the juice, improving its safety and shelf life.

- Other Foods

Pasteurization can be used to pasteurize a wide range of other foods, including sauces, soups, and other liquid foods. However, not all foods can be pasteurized, as the process may alter their taste, texture, or nutritional content.

Conclusion

Pasteurization is a process used to improve the safety and shelf life of food products. The process involves heating food to a specific temperature for a defined period of time to kill any pathogenic microorganisms that may be present. There are two main types of pasteurization: high-temperature short-time (HTST) and ultra-high-temperature (UHT) pasteurization. Pasteurization is commonly used in the food industry to pasteurize milk, cheese, yogurt, juice, and other beverages, among other products.