Biological Wastewater Treatment

Industrial wastes should be adequately treated before disposal in a receiving watercourse because it reduces the spread of pathogenic micro-organisms, prevents pollution and contamination, avoidance of health and aesthetic hazards, prevents objectionable odours, colours, and tastes, maintains the oxygen balance, etc.

The level of decomposable organic matter present in industrial wastewaters is measured in terms of ‘Biochemical or Biological Oxygen Demand’ (BOD) or ‘Chemical Oxygen Demand (COD). Biological oxygen demand measures the quantity of oxygen consumed during the biological decomposition of organic matter (oxidation) in one litre of waste water during a specified time (usually five days).

Chemical Oxygen Demand determines the milligrams of oxygen consumed per litre of waste water during the oxidation of the organic matter by hot acidified dichromate. Biological Oxygen Demand and Chemical Oxygen Demand determination can be employed at any stage in the treatment of industrial or municipal wastes so as to ascertain the efficiency of the treatment.

Industrial sewage contains both organic and inorganic compounds. The nature and amount of compounds depend upon the type of product and nature of the process involved in industry. Organic matter are readily degraded by micro-organisms due to a high content of sugars, proteins, urea, amino acids, amines, etc. Organic components in the sewage serve as food for micro-organisms. These micro-organisms oxidize the industrial wastes in presence of oxygen. If the organic content of the industrial wastes is high, the oxygen requirement is also more for oxidation of organic content.

Industrial waste treatment methods:

Industrial wastes are treated by different methods. The selection of method is dependent upon the cost of the plant, quantity, and nature of wastes, the sanitary requirement of health department etc. Treatment methods are classified as follows:

- Physical Method:

It is employed to remove suspended solids by using sedimentation tanks. Sedimentation tanks are circular or rectangular continuous flow tanks operating at the retention time of 6 to 12 hours. It can remove upto 60 to 70% of suspended solids and 30 to 40% of BOD load.

- Chemical Method:

Chemical treatment is done by flocculation or co-aggulation. Aluminium sulphate (alum )calcium hydroxide (lime), ferric sulphate and polyelectrolytes are often used coagulant and added into the effluent mixed tank. The suspended matter is precipitated and settled in the tank to form sludge.

- Biological Method:

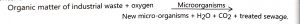

It involves use of microorganisms for the decomposition of substances. Various biological treatment methods are classified in Fig. 1.

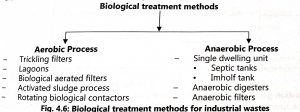

A Trickling filter consists of a bed of coarse pieces of stone, gravel and related substances. Individual rocks being two to four inches in diameter and the depth of the bed being approximately six to ten feet. This leaves many open spaces in the bed for penetration of air. Waste waters are sprayed over the rock bed continuously from nozzles located on a horizontal rotating arm (Fig. 2).

Waste water may be pre-aerated before spraying, although some aeration occurs during spraying. Micro-organisms such as bacteria, fungi, algae and protozoa become attached to the surface of the rocks. The large surface area permits close contact between flowing air, effluent and biologically active growth, which converts organic materials into simple form. The effluent waters are passed slowly through a final settling tank to remove the sloughed microbial cells and other debris before the waters are chlorinated and discharged into a stream.

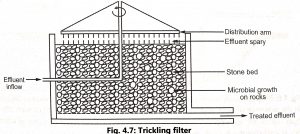

The Activated sludge process is a highly efficient system for the aerobic biological treatment of industrial wastes. The process is based on vigorous aeration of sewage. This practice of vigorous aeration causes the fine particles to clump into flocs. Such flocs are allowed to settle (Fig. 3) and then added to fresh sewage that is vigorously aerated. The process is repeated and most of the sludge is recycled from the sedimentation tank to the aeration tank.

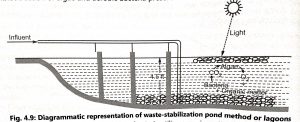

“Oxidation pond’ or ‘Waste stabilization pond’ is one of the most important method of sewage treatment in hot climates. It is also called ‘Lagoons’. Lagoonization is a natural process of sewage purification because oxidation of putrescible matter occurs through symbiotic action of algae and aerobic bacteria present in the effluent (Fig. 4).

In the presence of light and oxygen, bacteria utilize organic matter to convert into CO2 to algae, which will be utilized as a source of energy by photosynthesis and as nutrients. Oxygen is again helpful in the multiplication of aerobic bacteria.

Algae/light

6 CO2 + 12 H2O —————————–> C6H12O6, + 6 H20 + 602

glucose

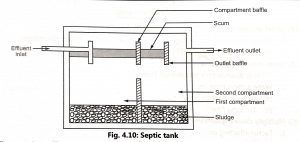

Septic and Imholf tanks (Fig. 5) are anaerobic digestion chambers used for the decomposition of simple or complex organic materíals to simple organic molecules and fermentation gases. These tanks are small, rectangular sited below ground level. The sewage enters into the first tank, where particles settle at the bottom (1 to 3 days), to form the sludge and are digested under anaerobic conditions. A thick crust of scum is formed at the surface which makes the system anaerobic. Solids not settled in the first tank are settled in the second tank. The sludge accumulated is removed once in every 1 to 5 years. The Imholf tank works as a septic tank but differ in its larger size and physical design.

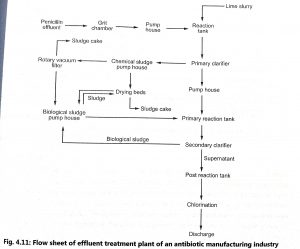

The complete effluent treatment plant of antibiotic manufacturing industry is shown as a flow sheet in Fig. 6.

REFERENCES