Autoclaves are instruments that are made to bear steam at a temperature of 121 degrees Celsius and pressure to sterilize them. The pressure and heat eliminate the bacteria, and other pathogens effectively so that autoclaves can be used extensively in medical facilities and laboratories for the preparation of life science application and culture media for microbiology, to sterilize medical instruments, glassware, and to decontaminate harmful medical waste after disposal.

Autoclaves are the sterilization apparatus of choice in hospitals and laboratories. They are also used in dentistry, veterinary medicine, development, and research of food production and pharmaceuticals facilities. Large and small autoclaves can be utilized anywhere considering the sterilization of the equipment is significant to ensuring the result of the process, the safety of public and person like in business which offers body piercing and tattooing services.

One of the issues with the autoclaving materials that are used in the process of sterilizing in the life science laboratories is moisture, heat, and pressure which may lead to some degradation. This is a major concern with media utilized for culturing microorganisms, as some of them may be thermolabile and can affect the performance negatively or render them unusable. With the advanced production of small and large autoclaves, this concern has been somewhat addressing as manufacturers have made these newer versions work at settings that offer thorough sterilization without leading to a critical reduction in the usability and performance of heat-sensitive materials.

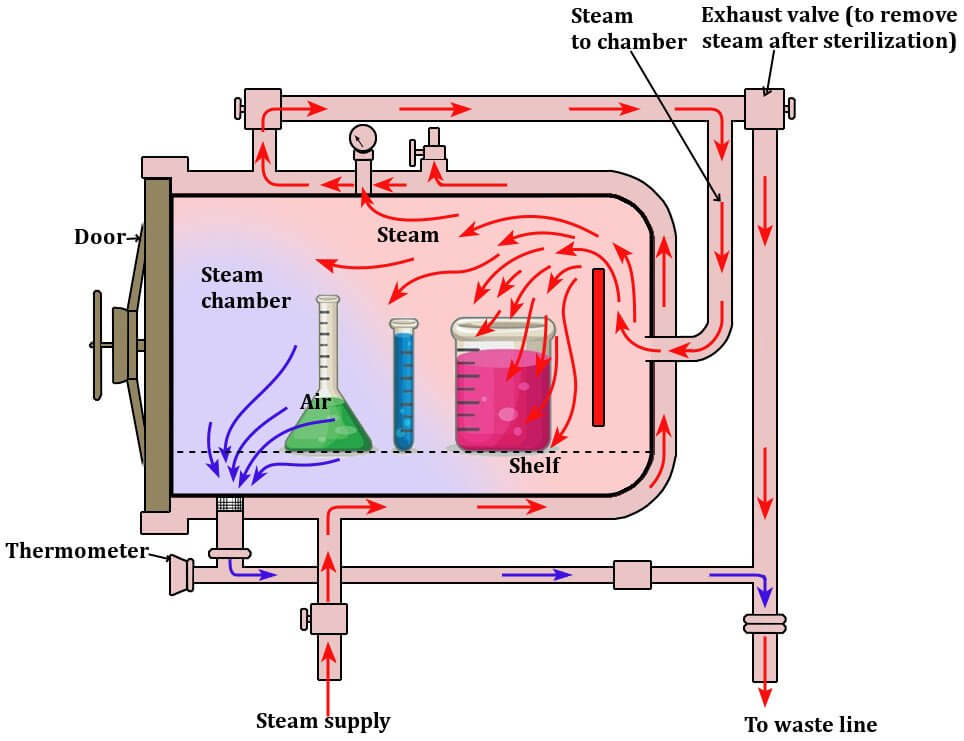

The high-pressure steam utilized in autoclaving offers effective means of sterilization than the application of only heated air. The high pressurized steam at 134 degrees C is typically used in autoclaves to sterilize it in few minutes as compared to 2 hours taken by the hot air at a temperature of 160 degrees C, making sure that the interior of the autoclave is free of air is important. In recent autoclaves, air can be removed by the steam action creating a downward displacement of air and pushing it out through a drain from the unit. Some of the autoclaves also use make use of a vacuum pump.

Autoclaves are also used in industrial applications where materials and parts require to be sterilized thoroughly during the process of production, this is comparatively less common in industries working with composite materials, specifically in the aerospace sector. Large-sized autoclaves may be needed to accommodate some of the components because of their sheer size. Safety is a matter of great concern while using these devices.

The large autoclave devices require to be designed to offer a security feature and closure of highly reinforced walls that can bear the rigors of round the clock and regular use. Autoclaves offer complete elimination of bacteria and other pathogens, ensuring the safety of the devices used in medical fields and decreasing the harmful threat posed by the veterinary waste, and permit more accurate outcomes in laboratory experiments.