Production of Streptomycin

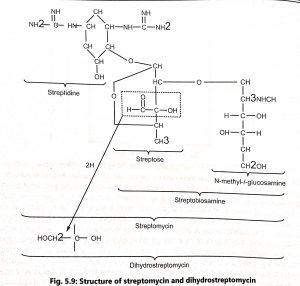

Streptomycin was the first aminoglycoside antibiotic, discovered by Selman A Waksman in 1944 that is very active against Gram-negative as well as Gram-positive organisms. The main use is for the treatment of tuberculosis due to their strong activity against Mycobacterium tuberculosis. Streptomycin was the first antibiotic produced from the Streptomyces genera (actinomycetes) from Streptomyces griseus. One of the antibiotic-producing strains of Streptomyces species is shown in Fig. 1. Streptomycin and dihydrostreptomycin are basic compounds and are usually prepared as salts. Streptomycin at high dosages may produce neurotoxic reactions. Hence, the chemical reduction of streptomycin to dihydrostreptomycin (Fig. 2) decreases this neurotoxicity.

Different strains are used for production of streptomycin and other derivatives (Table 5.1). Production yield was increased by the process of mutation and by culture media optimization. Production media includes sources of carbon and nitrogen and some essential materials. Glucose, fructose, galactose, xylose, mannitol, lactose, starch, dextrin or glycine can be used as sources of carbon and peptone, meat extract, glycogen, sayabean meal, corn-steep liquor, casein hydrolysate or nitrates are employed as source of nitrogen. Growth stimulating compounds (factor A, phenylacetic acid) antioxidants (agar or sodium sulphite). mineral salts and vegetable or mineral oils are often added in the fermentor. Merck’s media (glucose + soybean extract + NaCl), Schartz media (glucose + peptone + meat extract +NaCI) and Rake and Donovik’s media (glucose + soyabean extract + NaCl) are commonly used for the commercial production of streptomycin. Hockenhull (1963) described a typical industrial medium containing glucose (2.5%), soyabean meal (4%), distillers dried soluble (0.5%) and sodium chloride (0.25%).

Table 5.1: Strains used for production of streptomycin and other derivatives.

| Antiobiotic | Producer Strain |

| Streptomycin

| Streptomyces griseus, S. rameus, S. bikiniensis, S. erythrochromogenus

|

| Dihydrostreptomycin

| S. humidus

|

| Hydroxystreptomycin

| S. grisecarneus, S. subrutilus

|

Production:

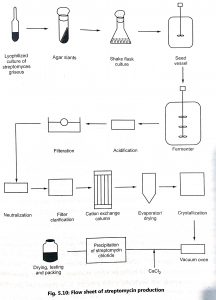

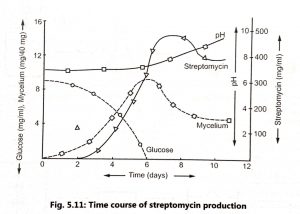

Flow sheet for production of streptomycin is shown in Fig. 3. Streptomycin yield in fermentation respond strongly to aeration and agitation. The optimum fermentation temperature is in the range of 25 to 30°C and the optimum pH ranges is 7 to 8. The fermentation lasts approximately 5 to 7 days (Fig. 4) and the fermentation passes through three phases.

Phase (I): The first phase (1 to 2 days) of streptomycin fermentation consists of mycelial growth. The proteolytic activity of Streptomyces griseus releases ammonia to the medium from the soybean meal and the pH rises to about 7.6 due to the production of ammonia. Glucose of the medium is slowly utilized with slight production of streptomycin.

Phase (II): In this phase (1 to 3 days) production of streptomycin increases at a faster rate without the growth of any new mycelium. Large quantities of glucose and oxygen are required and ammonia is utilized. The pH remains fairly constant in the range of 7.4 to 7.8.

Phase (III): In the last phase, sugar has been depleted from the medium and reduces the streptomycin production. The cells are lysed which then release ammonia and a rapid increase in pH. The streptomycin is isolated before the third phase.

Product recovery:

Streptomycin is recovered by different methods depending on the particular fermentation industry. The fermentation broth is acidified, filtered, and neutralized. It is then passed through a column containing a cation exchange resin to absorb the streptomycin from the broth. The column is washed with water and the streptomycin diluted with hydrochloric acid before concentration. The streptomycin is dissolved in methanol and filtered. Acetone is added to the filtrate to precipitate the antibiotic. Finally, the precipitate is washed with acetone and dissolved in methanol for preparation as a pure streptomycin calcium chloride complex.

REFERENCES