Production of Vitamin B12 (Cobalamin)

- Vitamin B12 is a water-soluble vitamin, commonly known as cobalamin. It is an important dietary component for normal growth in human beings and animals.

- Ricke E. L. and Smith L. (1948) isolated small amount of active material from liver and crystallized it as vitamin B12 Which was active in the treatment of pernicious anemia.

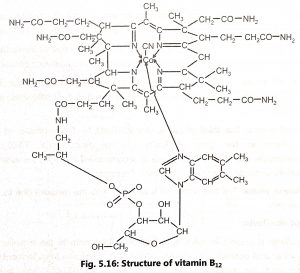

- Vitamin B12 is one of the largest and the most complex molecule. The main part in the structure of vitamin B12 is the porphyrin ring containing cobalt as the central element.

- The cyanide (CN) group, hydroxyl group (- OH) or nitrite group (- NO2) attached to the cobalt is called cyanocobalamin (vitamin B12), hydroxocobalamin and nitritocobalamin respectively. The structure of vitamin B12 is shown in Fig. below.

- Vitamin B12 is produced by bacteria and actinomycetes (Table below). Streptomyces olivaceus, Pseudomonas denitrificans, Propionibacterium shermanii and Propionibacterium freudenreichii are mainly used for commercial production of vitamin B12.

- Generally, vitamin B12 is prepared by the submerged culture process. Production of vitamin B12 from Streptomyces olivaceus have been discussed here.

| Microbial Growth | Species |

|

Actinomycetes

|

Streptomyces olivaceus, Nocardia species, Streptomyces albidoflavus, S. antibioticus, S. aureofacieus, S. griseus, S.roseochromogenus.

|

|

Bacteria

|

Pseudomonas denitrificans, Aerobacter aerogenes, Bacillus subtilis, Bacillus megaterium, Propionibacterium Shermanii,Propionibacterium freudenreichii, Clostridium butyricum, Flavobacterium acetylicum, Flavobacterium flavescens, Lactobacillus arabinosus, Mycobacterium smegmatis, Serratia marcescens, Proteus vulgaris, Streptococcus faecalis

|

Preparation of inoculum:

Pure culture of Streptomyces olivaceus is inoculated in inoculum medium contained in Erlenmeyer flasks. Bennett’s broth [yeast extract (0.1%), beef extract (0.1%), glucose (1%), and enzymatic hydrolysate of casein (0.25%)] is employed for the development of inoculum. Flasks are kept on the mechanical shaker during incubation for aeration. These flask cultures are used to inoculate a large amount of inoculum media. The required amount of inoculum (5% of the volume of production medium) is prepared by successive transfers.

Fermentation:

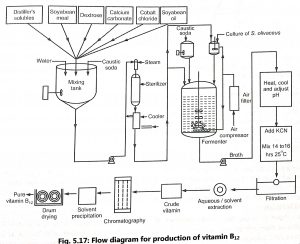

- The culture of Streptomyces olivaceus is grown with aeration at 28°C in a nutritionally rich crude medium. Distiller’s soluble (4%), dextrose (1%), and calcium carbonate (0.5%) are mainly present in typical production medium used in the production of vitamin B Cobalt chloride (COCIe 6H;0) at approximately 2 to 10 ppm is added to this medium as a precursor.

- The flow diagram for the production of vitamin Bz by Streptomyces olivaceus is shown in Fig. 5.17. The pH of the medium is adjusted to 7 to 7.5 before sterilization and may or may not be controlled during fermentation.

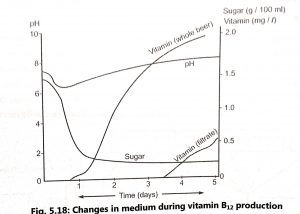

- In the first 24 hours, pH of fermentation is reduced due to rapid sugar consumption and again pH increases after 48 to 96 hours due to lysis of mycelium. The change in pH, sugar and production of vitamin B12 during a typical fermentation process is shown in Fig. 5.18.

- A correct rate of aeration and speed of agitation are required for proper growth of microbial strains. The optimum rate of aeration is about 0.5 volume air/volume medium/minute. Soyabean oil, corn oil, lard oil etc. are used as antifoaming agents to suppress foam formation.

Recovery of vitamin B12:

- Vitamin B12 is mainly associated with the mycelium of Streptomyces species. Most of cobalamin is recovered with the mycelium by centrifuging or filtering the whole beer after 3 to 4 days.

- Concentrated vitamin B12 is also obtained by reducing the pH of the beer to 5 with sulfuric acid and heating the mixture to boiling.

- Sodium sulfite (100 ppm) may be added in the mixture for the protection of vitamin. The medium is filtered to remove mycelium and then the filtrate broth is treated with cyanide to convert cobalamin to cyanocobalamin.

- The adsorption of the cyanocabalamin from the solution is done by using activated charcoal, fuller’s earth, bentonite etc.

- Finally, elution of cyanocobalamin is performed by using an aqueous solution of materials ranging from organic bases to hydrochloric acid.

- Single-step extraction into an organic solvent or counter-current extraction and product purification is carried out by the process of precipitation.

- Chromatography on alumina and final crystallization from ethanol-acetone is performed. The final product is drum-dried or spray-dried. The vitamin B12 content may vary from 10 to 30 mg/l in the final product.

REFERENCES