Types of fermentation

Introduction

The increase in the demand for biopharmaceuticals has to lead to an evolution in biotechnology engineering towards the development of bioreactors. The animal cell culture process has been used in the application in various diagnostic and therapeutic treatments. The large-scale production of recombinant proteins, hormones, enzymes, cytokines, antibodies, antibiotics, amino acids, and certain chemicals is fed by bioreactors or fermentors.

Fermentation Strategies for Large Scale Production

There are three possible fermentation strategies commonly utilized on an industrial scale:

- Batch Operation

- Continuous Operation

- Fed-batch Operation

Batch Operation

- The batch operation involves adding all necessary medium components and the inoculum in the beginning and not during the period of fermentation.

- Thus the concentrations are not controlled but varied as living cells take them up.

- The pH, dissolved oxygen, and temperature are normally held constant during the course of batch reactor operation.

- Suspension cultures were initially propagated and here cells grow in a finite volume of liquid nutrient medium and follow a sigmoid pattern of growth.

- All cells are harvested at the same time but the standby time is quite late.

- But this may face problems like nutrient limitation, low cell densities, low productivity, and high toxin accumulation which may lead to product degradation.

Continuous Operation

- Here, the fresh nutrient medium is added continuously to the fermentation vessel, while the effluent stream containing the cells, products, and residuals is continuously removed for the recovery of cells.

- A steady-state is established by maintaining an equal volumetric flow rate for the feed and effluent streams. While doing so, the culture volume is kept constant, and all nutrient concentrations remain at constant steady-state values

- Continuous cultures lead to achieving high cell density and high productivity without any nutrient limitation or growth inhibition due to toxin build-up in the system.

- But the continuous culture cannot be used in major industrial operations due to chances of contamination and loss of productivity and sometimes genetic change (mutation) also.

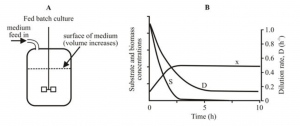

Fed-batch Operation

- Fed-batch is a boon in industrial operations that has the advantages of batch and continuous operations and minimizes the disadvantages of both possesses.

- A fed-batch culture is a semi-batch operation in which the nutrients necessary for cell growth and product formation are fed either intermittently or continuously via one or more feed streams during the course by manipulating the feed rates during the run.

- This process may be repeated a number of times if the cells are fully viable and productive.

- The products are harvested only at the end of the run which increases the culture volume during the course of operation until the volume is full

- They ensure prolonged cell growth (high cell densities) and product formation due to the extension of working time that is particularly important in the production of growth-associated products.