Types of fermenter

Fermenters are available in various sizes and their sizes are defined on the total volume capacity of the fermenter. According to size, fermenters are classified as follows.

- Small laboratory and research fermenter: 1 to 50 litre

- Pilot plant fermenter: 50 to 1000 litre

- Large size industrial production scale fermenter: more than 1000 litre.

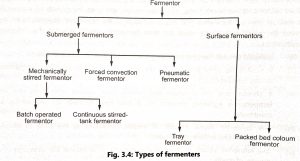

Small scale fermenters are autoclavable while large scale fermenters are sterilized by in situ sterilization. The small laboratory fermenters are designed to provide varying conditions for the growth of micro-organisms and are adjusted to provide similar growth conditions mainly found in the largest industrial production tanks. Broadly, the fermenters are also classified as submerged fermenters and surface fermenters (Fig. 3.4)

(1) Submerged fermenters:

In submerged fermenters (suspended-growth system), the micro-organisms are dispersed in nutrient medium (liquid) at maintained environmental conditions. On the basis of the mechanism of agitation, fermenters are further classified as follows.

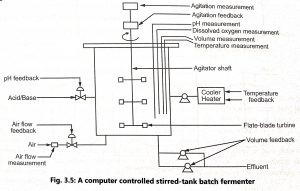

- Mechanically stirred fermenters: These fermenters are equipped with a mechanical agitator so as to maintain homogeneity and rapid dispersion and mixing of materials. Mechanically stirred fermenters are stirred tank fermenter, stirred multistage fermenter (continuous process), paddlewheel reactor and stirred loop reactor. Stirred tank fermenter is the most applicable fermenter in the fermentation industry for the batch process.

The main advantage of this fermenter is the flexibility in design and is used in the range of 1 litre to 100-ton capacity sizes. The agitators consist of one or more impellers mounted on a shaft. Different types of blades are used according to the requirements, It is rotated with the help of an electric motor. A basic computer-controlled stirred tank fermenter is shown in Figure 3.5.

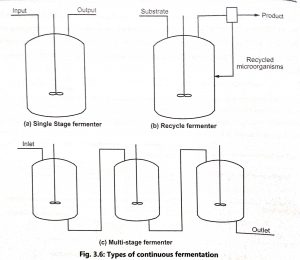

A continuous stirred-tank fermenter (CSTF) is basically the same as a batch fermenter. However, in addition to feed and overflow devices, the steady-state conditions can be achieved by ‘chemostatic’ or ‘turbidostatic ‘ principles. In continuous fermentation, fresh medium is added continuously in the fermentation vessel and in other end medium is withdrawn for recovery of fermentation products. A continuous fermenter can be conducted in various techniques. It can be performed as a ‘single stage’ in which a single fermenter is inoculated and then kept in continuous operation by balancing the input and output culture media [Fig.3.6 (a)]. In a ‘recycle’ continuous fermentation, a portion of the withdrawn culture or residual unused substrate plus the withdrawn culture is recycled to the fermentation vessel [Fig. 3.6.(b)]. The ‘multiple-stage continuous fermentation, involves two or more stages with the fermenters being operated in sequence (Fig. 3.6 (c).

Advantages of batch fermentation:

- Less risk of contamination or cell mutation because of short growth period.

- More flexibility with different product and biological systems.

- Process is more economical and simple.

- Raw material conversion level is more.

Disadvantages of batch fermentation:

- Low productivity due to the time required for sterilizing, filling, cooling, emptying, cleaning etc.

- More expenses are required for subcultures for inoculation, labour and process control.

- More focus on instrumentation due to frequent sterilization.

- Larger industrial hygiene risks due to potential contact with pathogenic microorganisms.

Advantages of continuous fermentation:

- Less labor expense due to automation of fermentation process.

- Less toxicity risks to operator by any toxins producing by micro-organisms.

- High yield and good quality product due to invariable operating parameters and automation of the process.

- Less stress on fermenter as sterilization is not very frequent.

Disadvantages of continuous fermentation:

- Uniformity in media quality is necessary to ensure that the process remains continuous.

- Higher investment cost in control and automation equipment.

- More risk of contamination and cell mutation.

- Slight variation only is possible in the continuous process.

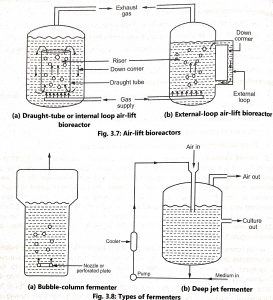

- Forced convection fermenters: In forced convection fermenters, the agitation is affected by using a pump, instead of a mechanical stirrer. ‘Loop fermenter and deep jet fermenter are available involving liquid movement and gas entertainer. In the loop fermenter, gas distribution device is a subsidiary vessel, where a liquid saturated with gas is circulated by forced convection into the fermenter vessel. In deep jet fermenter, gas is entertained into a high power jet of liquid into the liquid of the fermenter. Two different types of forced convection fermenters are available i.e. gas-lift or air-lift fermenter and bubble column or sparged tank fermenter. Different forced convection fermenters are shown in Figure 3.7 and Figure 3.8.

Air-lift fermenters are classified as draught tube or internal loop fermenter and external loop fermenter. In the gas-lift fermenters, internal liquid circulation in the vessel is achieved by sparging the vessel with gas. Fluid volume of the vessel is divided into two interconnected zones by draught tube. Air is typically fed through a sparger ring into the bottom of a central draught tube that controls the circulation of air and the medium. The airlift external-loop reactor system is used for circulation of direct air and liquid throughout the vessel, This system consists of a riser and an external down comer, which are connected at the bottom and the top respectively. The injected air at the bottom of the riser creates gas bubbles that rise through the fermentation tank and the heavier solution descends through the down comer. The external-loop airlift reach system has some advantages as compared to standard airlifts (Internal-loop reactors). These are:

- Easy measurement and control in the riser and the down comer.

- Efficient temperature control and heat-transfer.

- Low friction with an optimal hydraulic diameter for riser and down comer.

- Specific residence time in the individual section.

Bubble column reactor is a cylindrical column, in which the gas is sparged at the bottom through nozzles on a perforated or porous distributor plate. The gas bubbles rise through the liquid in the vessel and may be redispersed by a succession of horizontal perforated baffle plates. Temperature controls are maintained by the temperature jacket or the internal coils.

Air-lift fermenters provide many advantages as compare to the standard fermenter.

- High flexibility, less shear rate.

- Controlled flow and efficient mixing.

- Simple design without any moving parts like agitator.

- Easy maintenance, less risk of defects and easy sterilization.

- Specific defined residence time for all phases.

- Large volume tanks, possible specific interfacial contact-area with low energy input.

- Higher mass-transfer due to enhanced oxygen solubility achieved in larger tankwith greater pressure.

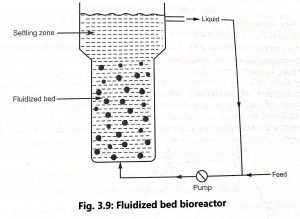

- Pneumatic fermenter: Fluidized bed bioreactor is an example of pneumatic bigreactor used in fermentation involving fluid with suspended particulate biocatalyst(enzyme) or cell particles or microbial flocs (Fig. 3.9). The cell particles are fluidized with up-coming stream of liquids. Top part of the fluidized fermenter is expanded to reduce Superficial velocity of fluidized bed. Solids set easily in setting zone and then dropped into fluidized zone.

(II) Surface fermenters:

Microbial cells are cultured on the surface layer of the nutrient medium (solid/ liquid) held in a dish or a tray and is generally called as surface culture system or supported growth system. This technique is commonly used for production of citric acid from Aspergillus niger and nicotanic acid from Aspergillus terrus. Microbial films can be developed on the surfaces of suitable packing medium. This may be in the form of a fixed bed, stones or plastic sheets.

This system is commonly used in biological waste water treatment. Packed bed column fermenter and tray fermenter are the example of surface fermenters.

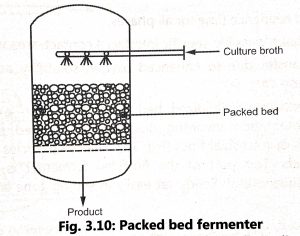

- Packed bed column fermenter: This is type of surface culture bioreactor in which solid particles form the packed bed on which enzymes are immobilized. A liquid nutrient is allowed to flow continuously through the packed bed. Metabolic products are released in the fluid and removed in the outflow (Fig. 3.10). When the film of micro-organisms is formed on the surface of packing material then this is called is film bioreactor.

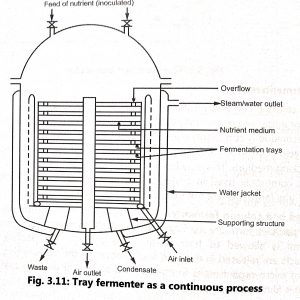

- Tray fermenter: In tray fermenter, solid as well as liquid media are used for fermentation. If liquid medium is used, cells are allowed to float easily and to make the process continuous (Fig. 3.11). If solid medium is used for tray fermenter then the process is called as solid state fermentation.

Solid state fermentation is defined as the growth of microorganisms (mainly fungi) on moist solid materials in the absence of free-flowing water. These processes have been used for the production of antibiotics, alkaloids, enzymes, organic acids, and also for bioremediation of hazardous compounds, biological detoxification of agro-industrial residues, nutritional enrichment, biopharmaceutical products etc. Solid state fermentation (SSF) has become a more attractive alternative to liquid fermentation for many productions.

Advantages of solid state fermentation:

- Solid state fermentation produce higher yields than submerged liquid fermentation.

- The possibilities of contamination by bacteria and yeast are very less because of low availability of water.

- All natural habitats for fungi are easily maintained in solid state fermentation.

- Culture media are very Simple and it provides all the nutrients for growth of micro-organisms

- Simple design of fermenter and low energy requirements.

- Small reactors are used due to concentrated nature of the substrate.

- Low moisture availability may favor the production of specific compounds.

- Inoculations with spores (fungi) facilitate its uniform dispersion through the medium.

Disadvantages of solid-state fermentation:

- The solid nature of the substrate causes problems in the monitoring of the process parameters (pH, moisture content, substrate and oxygen concentration).

- Agitation and biomass determination is very difficult.

- Solid-state fermentation is only suitable for microorganisms that can grow at low moisture levels.

- The substrates require pre-treatment such as size reduction, homogenisation, chemical or enzymatic hydrolysis, vapours treatment etc.

- Possibility of contamination by different types of undesirable fungi.

- Aeration may be difficult due to the high level of solid contents.

- Spores have larger lag times due to the need for germination and also require more cultivation times.

- Products obtained by leaching fermented solids are often vicious.

Design of fermenter:

The fermenter is a system consisting of different types of equipment to provide microbial growth by controlling environmental conditions. A typical fermenter consists of three parts such as the culture vessel, associated supply and environmental systems and measurement and control system. The various designing aspects required to be considered in constructing an ideal fermenter for the production of pharmaceuticals are:

- Provide operation free from contamination.

- Adequate mixing and aeration.

- Maintain specific temperature and pH.

- Access points for inoculation and sampling.

- Non-toxic to microorganisms and safe.

- Minimize liquid loss from the fermenter.

- Monitoring and control of dissolved oxygen.

- Allow feeding of nutrient solution and reagent.

- Suitability for a wide range of microbial cultures.

- Minimal use of labour and finances.

- Cheapest materials and smooth internal surfaces for vessels.

The fermenter is made up of stainless steel or borosilicate glass. They are non-corrosive, non-toxic and easily cleanable. The head plates provide parts for nutrient medium probes, gas input and waste product removal. Head plates and other accessories are fitted to the vessel by making use of gaskets, lip-seal and silicon rubber o-rings. Aeration and agitation are achieved by using stirrers, baffles, agitators (impeller), paddles and aeration system (sparger). Agitation and aeration system is one of the major requirements of aerobic fermentation.

Measurement and control of environmental conditions and biological variables are called fermentation monitoring. New developments in digital electronics have permitted a high level of monitoring and control of fermentation processes. The computer can be a vital instrument for process optimization and control.