Introduction:

Hot air oven is developed by Pasteur. It is thermostat controlling device based on utilization of dry heat for sterilization of object. Now a day’s digitally controlled ovens are also available. Hot air oven is double walled device made up of aluminium or stainless steel where inner case is separated from the outer case by thick layer of insulation. It helps to maintain temperature inside and also prevent heat loss. Hot air ovens are usually used for sterilization of those materials which are stable at high temperature (up to 250°C).

Principle:

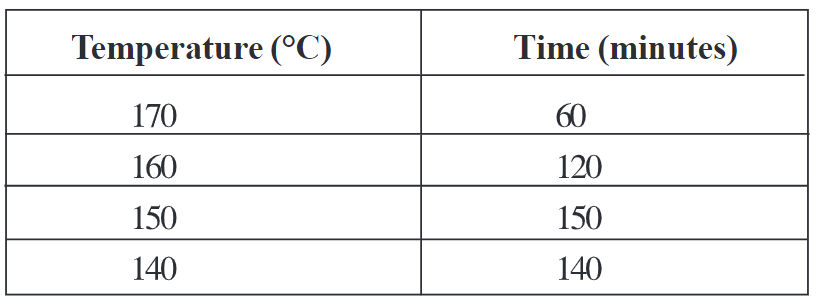

Dry heat sterilization is used to destroy spores as well as vegetative forms of all microorganisms. In addition, dry heat effectively destroys the pyrogens at double holding time. The mechanism by which microorganism are killed by heat is through coagulation of protein of cell. Time required for sterilisation is depends on condition of temperature. Relation between holding time and temperature in Table No.1

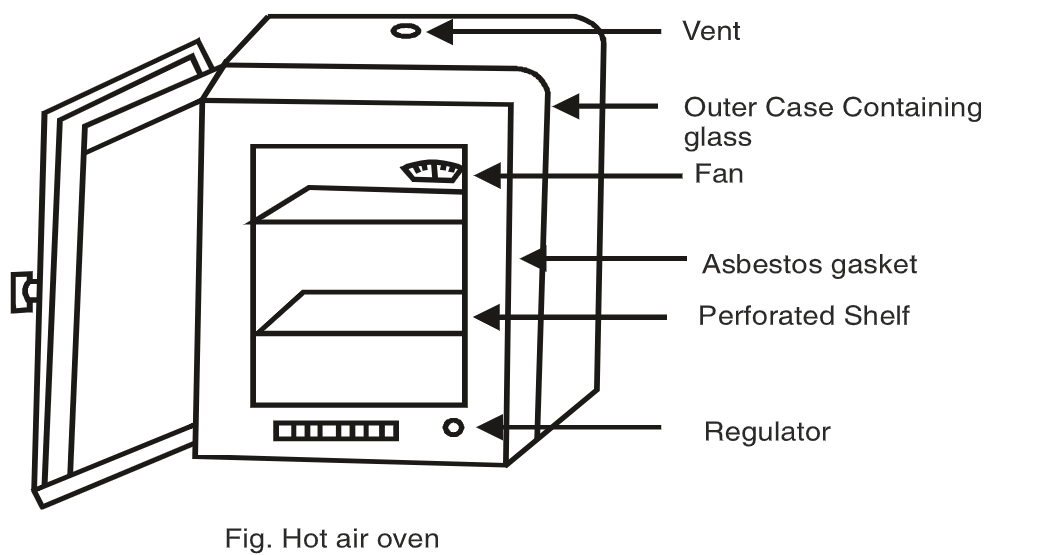

Construction

Hot air oven is double walled device whose outer case is made up of mild steel or stainless steel which is coated with thick layer of stoved epoxy polyester paint. It provides heat resistance surface to oven. Inner case is made up of aluminium or stainless steel material. In between two cases insulating material like fibreglass, glass-wool is present.

Hot air oven is fitted with heating element like nichrome wire which is further coated with nickel or chrome. For efficient working, heating element is placed at the bottom as well as in both sides of the chamber. Fan is also equipped inside the chamber, to ensure uniform distribution of hot air. Two or three perforated shelves are fixed inside the oven to place the materials for sterilization. Thermometer is fitted in the oven to check the temperature inside the oven.

Working: Materials to be sterilised are placed on shelves in such a way that heat get uniformly circulated between the objects. Glass materials are dried completely and wrapped with Kraft paper prior to sterilization. Once the material is placed inside the oven, door is closed down and instrument is switched on. Temperature is monitored frequently through thermometer and once it reaches to desired level from that time material is hold for particular time as given in Table No. 1. After holding time, oven is switched off and allowed to cool down slowly (~2h). Avoid the opening of door immediately which may causes cracking of glass wares.

Applications:

1. It is mainly used for the sterilization of glass wares like pipettes, bottles test tubes, Petri dishes etc.

2. It is used for sterilization of powders as well as oils which is not possible by moist heat sterilization.

3. Injectable can be sterilized by hot air oven.

4. Hot air oven is used for sterilization of scalpels, scissors, spatula, blades and glass syringes.

Advantages:

1. It kills spores as well as vegetative forms of all microorganisms.

2. Dry heat effectively destroys the pyrogens which is not possible with moist heat steriliser.

3. Samples lacking of moisture like powders and oils can be sterilised by hot air.

Disadvantages:

1. Not suitable for heat-labile subjects like rubber, plastic, surgical dressing etc.

2. Dry heat possesses low penetration power.

3. It requires long exposure times to achieve proper sterility.

Precautions:

1. Glass apparatus must be wrapped with the Kraft paper or filter paper.

2. Do not keep the material at the bottom where it receives relatively more heat which may cause cracking of material.

3. Keep space in between material for proper circulation of hot air. Avoid over loading.