Contents:

Introduction:

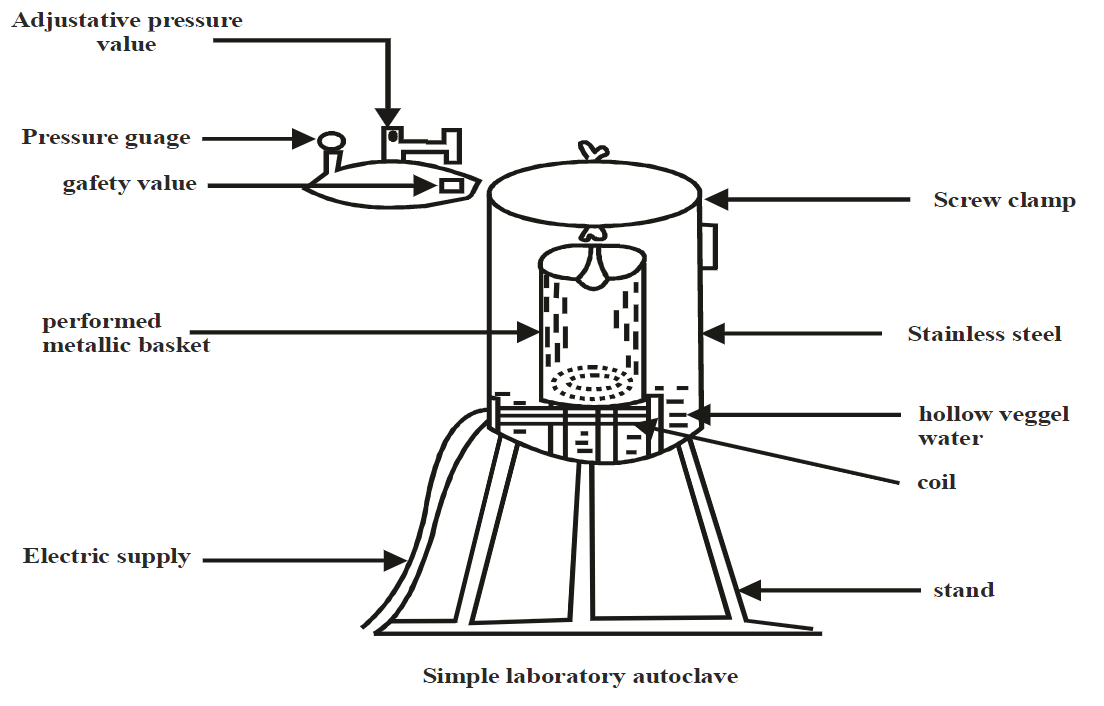

Autoclave is a large vessel through which steam is circulated for sterilization of object. Various scientific experiments and industrial processes are carried out by autoclave. Autoclave is a cylindrical vessel made up of stainless steel which is able to withstand extreme pressure for sterilization. It is just like a pressure cooker which is based on the steam under pressure principle. With the help of steam, autoclave destroys the microorganisms which are present on the object. Autoclave is used for the applications requiring constant pressure and temperature for long period of time. The majority of autoclave function is a use of heat and maintaining a temperature constant for complete sterilization.

Nowadays, modified autoclaves are also available including cold sterilizers, gas sterilizer autoclave and ultraviolet autoclaves.

Principle:

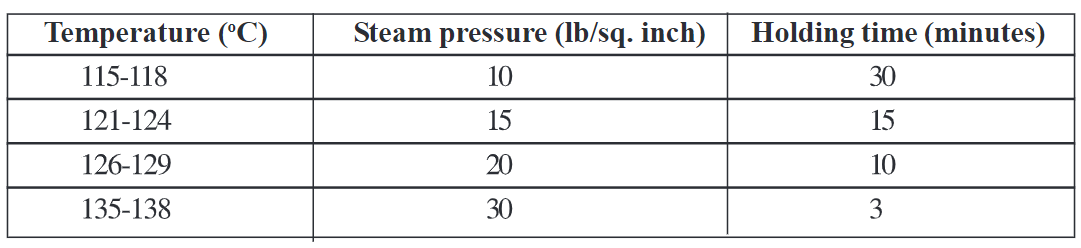

Moist heat generated by autoclave is more effective than dry heat for thermal sterilization. Moist heat causes coagulation of cell protein at much lower temperature than dry heat. Additionally, thermal capacity is much greater than hot air. In autoclave, water is boiled till its vapour pressure equals that of surrounding. When pressure inside the vessel increases to 15 Ib/sq inch, it also increase temperature of steam from 100°C to 121°C. When saturated steam strikes with cold subject it undergoes condensation where it librates heat equal to 524 calories per gram which is around 500 times more than hot air. Consequently, object get heated rapidly and undergoes sterilization. Time required for sterilization is variable depending on condition of temperature and pressure. Holding time and condition of temperature and pressure Is given in Table 1.

Working:

A sufficient quantity of water is poured into the chamber and the level of water is adjusted in such a way that it is slightly touching to the bottom of the perforated chamber. The material is packed in the perforated chamber. The lid is then closed with the screw and the autoclave is switched on. Initially, discharge tap is kept open and safety valve is adjusted to required pressure. As the temperature of water increases, it starts to vaporise and result in the formation of stem. This steam removes the air from autoclave which is indicated by formation of air bubble at discharge valve. When air bubbles stop emitting from discharge tap, it indicates that complete air has been removed out. At this stage the discharge valve is closed. Once steam pressure reaches to desired value, safety valve is set open. From this point subject is hold for time as specified in table 1. After holding time autoclave is switched off and allows cooling. Then lid is opened and sterilized materials are taken out.

Type of the autoclave:

- Simple laboratory autoclave

- Transportable benchtop autoclave

- Large simple autoclave

- Downward displacement laboratory autoclave

- Media propagators

- Multipurpose laboratory autoclave

- High security autoclave

- Porous load sterilizers

- Low-temperature steam

- Other autoclave

Applications of Autoclave:

1. Autoclaves are widely used in microbiology, veterinary science, mycology etc.

2. It is used to sterilize wide range of material including but not limited to laboratory glasswares, laboratory equipments and instruments, surgical material including needles, seizures, heat-stable hand gloves, containers, and closures etc.

3. Autoclave is most commonly involved in the sterilization of biological media.

4. Various pharmacopeias have recommended autoclave for sterilization of number of Injectable.

5. A growing application of autoclave is the pre-disposal treatment and sterilization of waste materials which are released from pathogenic area like Hospitals waste.

Advantages

1. Autoclave is more efficient than dry heat.

2. It kills all types of bacteria, fungi including spores.

3. A large number of materials can be sterilized in one batch by using a big autoclave.

Disadvantages:

1. Not suitable for heat-labile substances.

2. Normal cycle fails to destroy pyrogens.

3. It is not suitable for the sterilization of powders and oils.